1. Basic structure of composite geomembrane

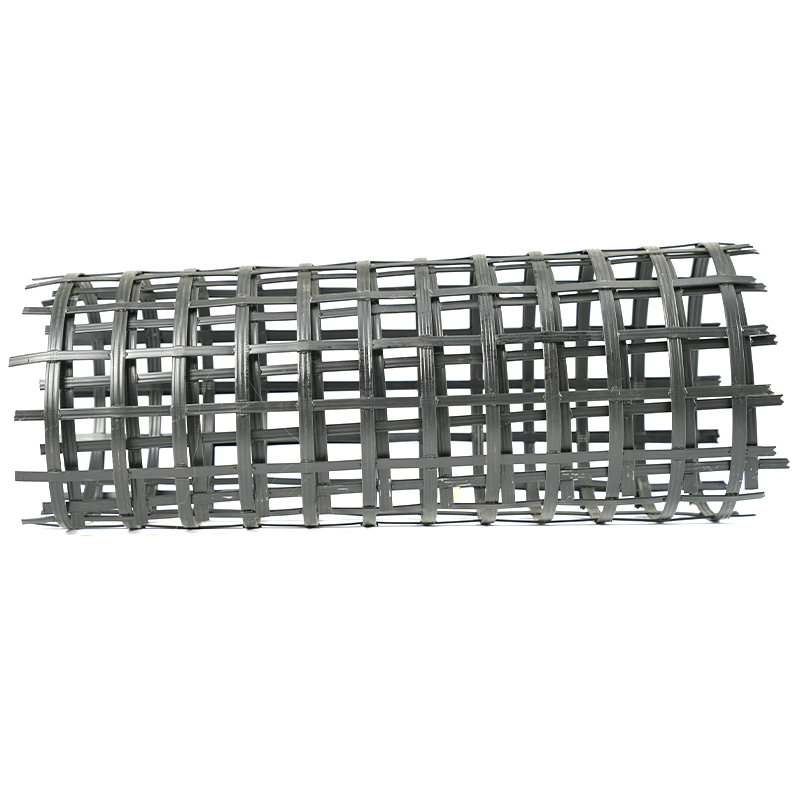

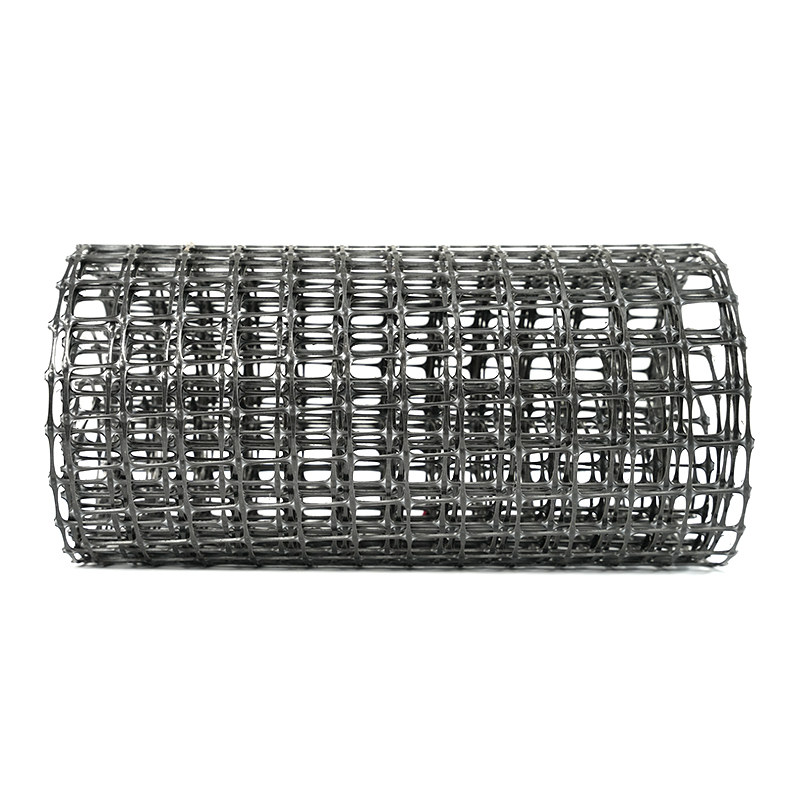

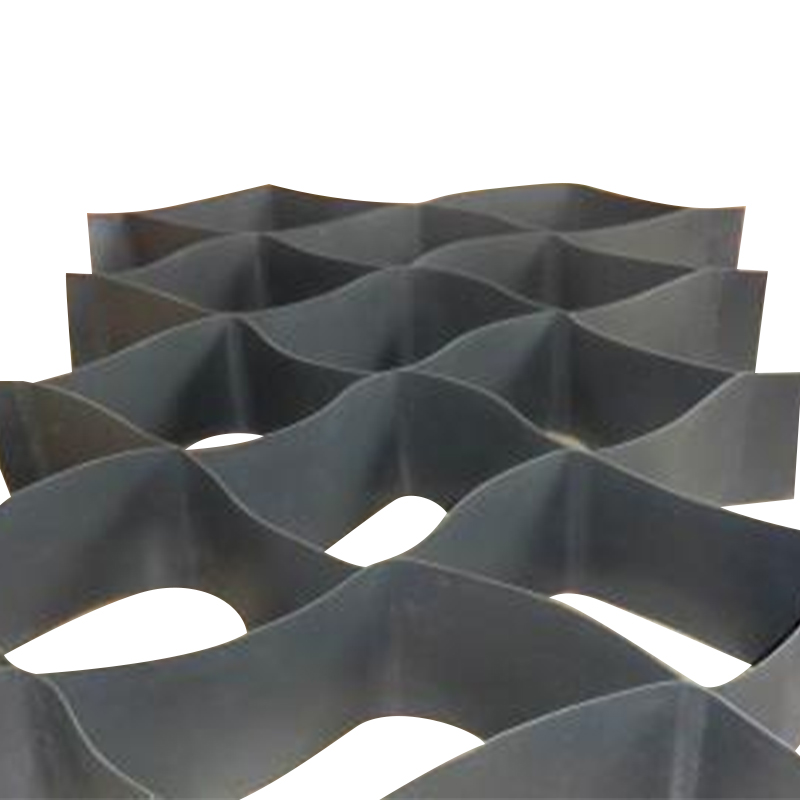

Composite geomembrane usually consists of three layers: an anti-seepage membrane layer and one to two layers of protective geotextile. Its basic structure is as follows:

Anti-seepage membrane layer: This layer is the core part of the composite geomembrane and is mainly made of materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). The main function of the anti-seepage membrane layer is to prevent the penetration of water and other liquids and ensure the waterproof performance of the engineering structure. The thickness of the anti-seepage membrane is generally between 0.2 mm and 0.8 mm. This thickness range can balance the flexibility and strength of the membrane, thereby providing anti-seepage effect.

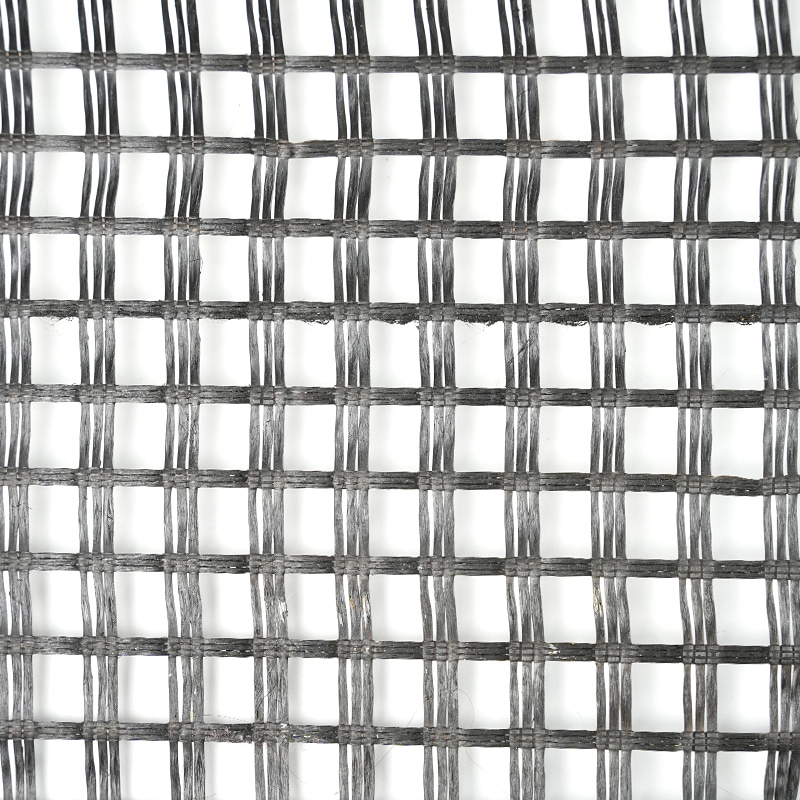

Protective geotextile layer: The protective geotextile layer of composite geomembrane is divided into two types: one cloth and one membrane and two cloths and one membrane. The protective geotextile layer is located on both sides of the anti-seepage membrane, which plays the role of protecting the membrane layer and enhancing its puncture resistance and durability. The thickness of geotextiles ranges from 100 g/m2 to 800 g/m2, which can effectively resist sharp substances and mechanical damage in the soil, thereby extending the service life of the composite membrane.

2. Material properties of the anti-seepage membrane layer

The material selection of the anti-seepage membrane layer is crucial to the anti-seepage performance of the composite geomembrane. High-density polyethylene (HDPE) has become a commonly used anti-seepage membrane material due to its corrosion resistance and low permeability. The HDPE membrane layer has high chemical stability and mechanical strength, and can provide long-term and stable anti-seepage effects under various environmental conditions. The polyvinyl chloride (PVC) membrane layer excels in flexibility and adaptability. Although its aging resistance and temperature resistance are slightly inferior to HDPE, it is still an effective anti-seepage material.

3. The role of protective geotextiles

The protective geotextile layer has a significant impact on the overall performance of the composite geomembrane. The main function of the geotextile is to protect the anti-seepage membrane layer from external damage and improve the puncture resistance of the composite membrane. The fiber structure and thickness of the geotextile determine its protective effect. High-quality geotextiles can effectively isolate soil particles and prevent sharp objects from penetrating the membrane layer, thereby improving the overall durability of the composite membrane.

4. The impact of process manufacturing

The production process of composite geomembrane has a direct impact on its anti-seepage performance. The bonding technology of the membrane layer and the geotextile is crucial. Common bonding methods include thermal welding and adhesive sealing. The thermal welding process can ensure a firm bond between the membrane layer and the geotextile, avoiding leakage problems caused by poor bonding.

5. Application advantages of composite structures

Composite geomembrane performs well in a variety of application scenarios due to its unique structural design. For example, in landfills, composite membranes can effectively isolate leachate and prevent pollution of groundwater resources. In the construction of dams and reservoirs, composite membranes are used to control water seepage and ensure the stability of engineering structures.

中文简体

中文简体 русский

русский عربى

عربى