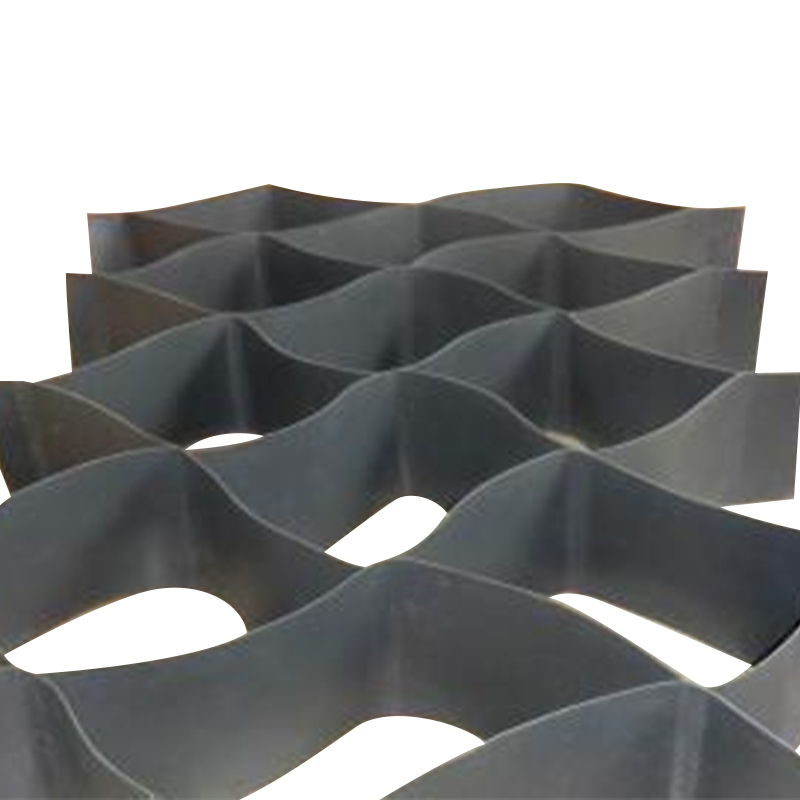

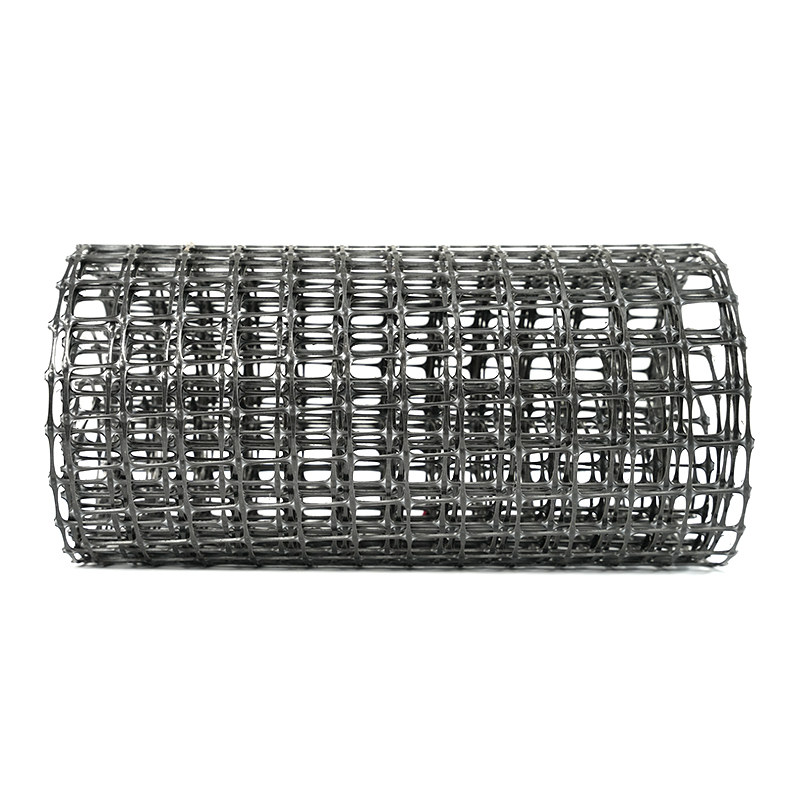

Geocell

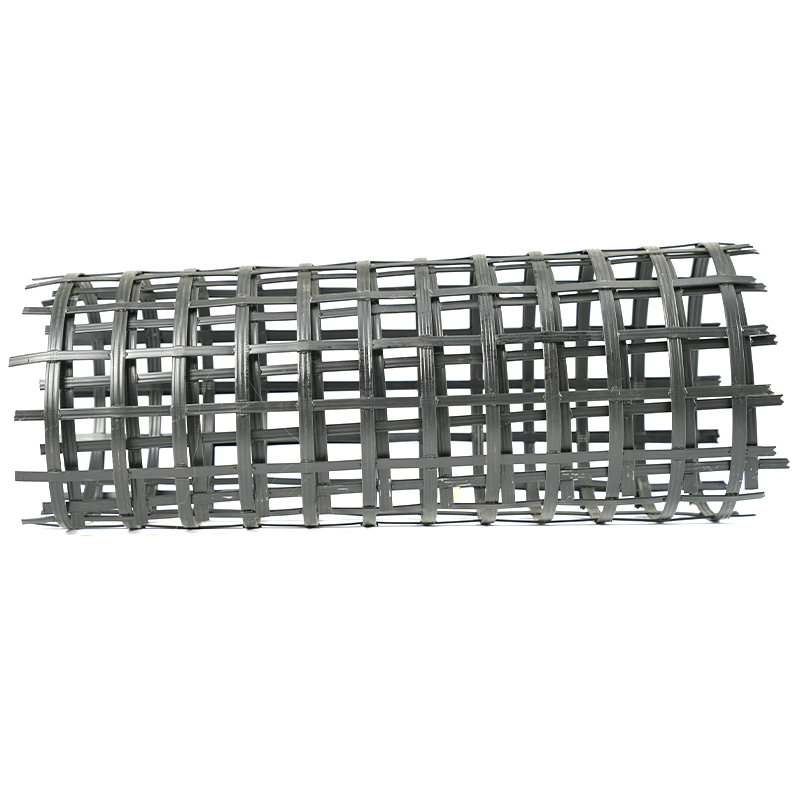

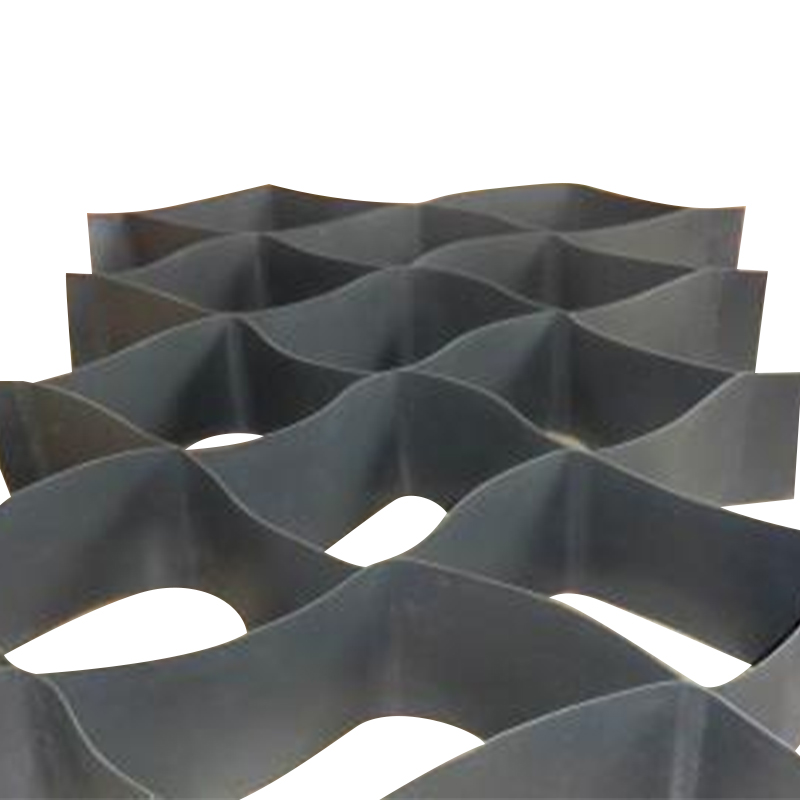

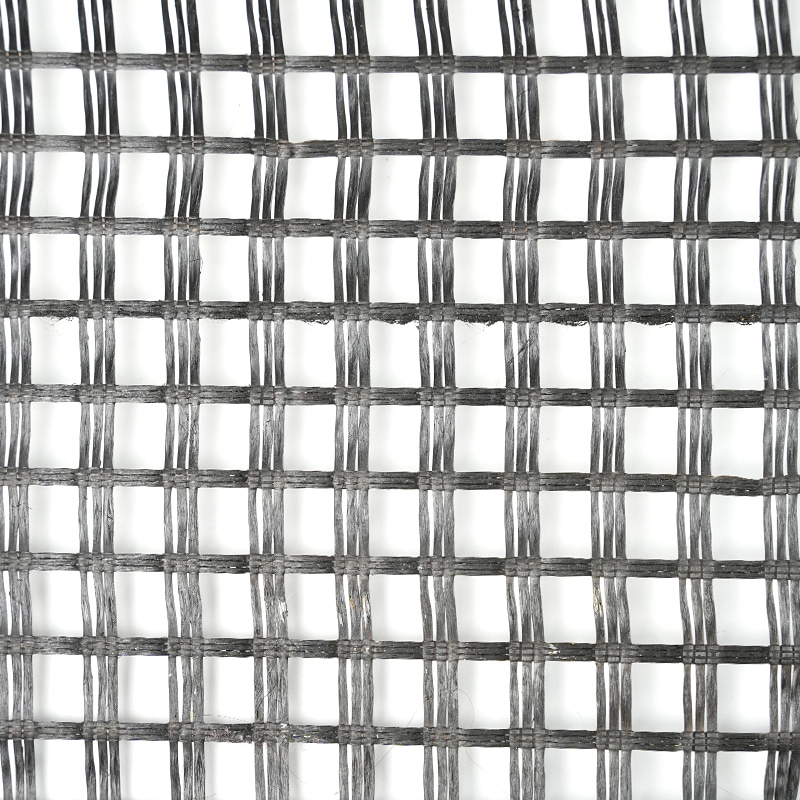

Geocell is a three-dimensional mesh chamber structure made of reinforced HDPE sheet material, which is formed by high-strength welding. Generally made by ultrasonic needle welding. Due to engineering needs, some of them are perforated on the membrane sheet.

Characteristic

1. It can expand and contract freely, and can be transported and folded, and it can be tensioned into a mesh during construction, filled with loose materials such as soil, gravel, concrete, etc., to form a structural body with strong lateral restriction and large stiffness.

2. Light material, wear-resistant, chemically stable, resistant to light and oxygen aging, acid, and alkali resistance, suitable for different soil and desert and other soil conditions.

3. Higher lateral restriction and anti-skid, anti-deformation, effectively enhance the bearing capacity of the roadbed and disperse the load effect.

4. changing the geocell height, welding distance, and other geometric dimensions can meet different engineering needs.

5. Expansion and contraction freely, small transport volume; convenient connection, fast construction speed.

Get A Quote

-

Basic PrincipleThe reason why geocells have received so much attention from the engineering community for their good performance begins with their basic principles. The principle is described in foreign literature as "a cellular, three-dimensional confinement system that significantly improves the performance of common fill materials in a wide range of load-bearing and erosion control applications." Its key principle is three-dimensional confinement. As we all know, when a car travels across the desert, it presses out two deep ruts, with the pressed portion sinking deeply and the sides of the rut rising high. If the vehicle behind continues to follow the rut, the sunken part will sink further, and the raised part will rise further, until the raised part rubs against the chassis of the car, and the sunken rut buries of the wheels, thus making it impossible to move forward. The reason for this is that when the external load acts on the foundation surface, according to the Plumtree theory and Taylor's theory can be known: under the action of the concentrated load, the active zone 1 is pressurized to sink, and the force will be decomposed to both sides to be transferred to the transition zone 2, and the excessive zone 2 will be transferred to the passive zone 3, and the passive zone will be deformed without any restriction and bulge.Product features:1, expansion and contraction, transport can be shrinking stack, construction can be tensioned into a net, filled with soil, gravel, concrete, and other loose materials, constituting a strong lateral restriction and large stiffness of the structural body.2、Light material, wear-resistant, chemically stable, resistant to light and oxygen aging, acid, and alkali resistance, suitable for different soil and desert and other soil conditions.3、Higher lateral restriction and anti-skid, anti-deformation, effectively enhance the bearing capacity of the roadbed and disperse the load effect.4, changing the geocell height, welding distance, and other geometric dimensions can meet different engineering needs.5、Expansion and contraction freely, small transport volume, convenient connection, fast construction speed. That is to say, once the load acts on the roadbed, the active region in the shape of a chevron will be formed under the load, which in turn extrudes through the transition region, thus causing the passive region to bulge. In other words, the bearing capacity of the foundation is determined by the shear force along the slip line and the forces that move the active, transition, and passive regions. Not only is the true process of the above principle very evident in sand bases, but samples of it are also found in soft-base highways, except that the rate of formation is slower than the sand change. Even the road-based materials are not immune to lateral movement. Typical motorway foundations are several meters above ground level, so water absorption and slurry are less likely, but long-term settlement still exists. The reason, rainwater infiltration, material loss, and base subsidence are part of the reason, the roadbed pavement in the wheel load long-term crushing, vibration force, and the material to the roadbed section on both sides of the lateral displacement is undeniably another very important reason. All levels of highway in our province, for example, there are in the road on the main carriageway can feel the road surface has been pressed out of an "S" type ditch-like band. Part of the highway is no exception, the car driving in the carriageway bumps significantly stronger than driving in the feeling of overtaking the belt, in the road and bridge section is particularly obvious (commonly known as "bridge jumping car"). This ditch-shaped roadbed settlement is the typical lateral slip of roadbed material.Conventional treatment of roadbed in the project need not be repeated, its purpose is to improve the foundation material shear resistance and friction, reduce or delay the foundation material in the load pressure or vibration under the action of the ability to move, and thus the requirements of the project on the material will inevitably have a lot of harsh limitations, if you can't get the required materials, you need to purchase these materials, the cost of purchasing materials and transport costs accounted for a very large part of the overall project cost. The cost of purchasing materials and transport costs account for a large part of the cost of the whole project. And the use of geocells can be on the spot or near the material, and even can not be used in the regular situation of the material, thus greatly reducing the material purchase costs and transport costs. Why is this so? Geocell load-bearing situation schematic: in the concentrated load, the force of the active zone 1 will still transfer the force to the transition zone 2, but due to the lateral restriction of the chamber wall and the reaction force of the neighboring chambers, as well as filler and chamber wall friction formed by the lateral resistance to inhibit the lateral movement tendency of the transition zone 2 and the passive zone 3, to enable the roadbed load-bearing capacity can be improved. After testing, the apparent cohesion of medium-dense sand can be increased by more than thirty times under the restrictive effect of the lattice chamber. If you can increase the shear force of the roadbed material or inhibit the movement of the three regions can be achieved to improve the effect of the bearing capacity of the foundation, which is the restriction principle of the geocell. Geocell, as a new type of synthetic material, in the late eighties and early nineties, Europe the United States, and other countries began a lot of research and development work, and by the test and field application proved to improve the general fill to withstand dynamic loads as well as the roadbed protection have great efficacy. China in the early nineties in the absorption of foreign advanced experience based on the development of geocells began the research work, and in the roadbed disease remediation, the application of fixed loose media has made a breakthrough. With a further understanding of the characteristics of the geocell, it has been found that it has other geomaterials (geotextile, geomembrane, geogrid, geomolding bags, geonets, etc.) irreplaceable advantages so that it has unique application prospects in many fields.Application1、 Handling of half-filled half-roadbedWhen constructing an embankment on the slope with a natural ground gradient less than 1:5, the base of embankment should be excavated with steps, and the width of the steps should not be less than 1M, and when widening the highway by phased construction or reconstruction, the steps should be excavated at the interface of the old and new roadbed fill slopes, and the width of the steps of the high-grade highway should be 2M, and geogrids should be laid on the horizontal surface of each step to solve the problem of uneven subsidence by utilizing the side-limit reinforcing effect of geogrids themselves. The problem of uneven subsidence can be better solved by using the reinforcement effect of the geocell's elevation side limit.2. Roadbed in wind and sand areaRoadbeds in the windy and sandy areas should be mainly low embankment, the filling height is generally not less than 0.3M. Due to the low roadbed and heavy bearing professional requirements of roadbed construction in windy and sandy areas, the use of geocells can play a side-limiting effect on the loose filler to ensure that the roadbed has a high stiffness and strength within a limited height to withstand the load stress of large vehicles.3、 Reinforcement of the fill of the roadbed behind the platformThe use of geocells can better achieve the purpose of reinforcement of the back of the platform, geocells and fill can produce enough friction between the roadbed and structures to effectively reduce the uneven settlement, and ultimately to effectively alleviate the "abutment jumping" disease on the bridge deck of the early impact damage.4, perennial frozen soil area roadbedIn the perennial permafrost region building fill roadbed, should reach the fill height, to prevent the occurrence of slurry or cause the upper limit of the frozen layer down, resulting in excessive settlement of the embankment. Geocell's unique facade reinforcing effect and effective implementation of the overall lateral limitation can ensure the filling height in some special areas to extent, and make the filling soil with high-quality strength and stiffness.5、 Yellow earth wet subsidence roadbed treatmentFor highways and primary roads through the wet trapping loess and compression of the loess section, or high embankment foundation bearing capacity is lower than the vehicle load and embankment weight pressure, but also according to the requirements of the bearing capacity of the roadbed treatment, then the goodity of the geocells on the manifestation of the undoubted.6、 Salt soil, swelling soilSalted soil, swelling soil construction of highways, highways, shoulders, and slopes are used to strengthen measures, the effect of reinforcing the façade of the chamber is one of the of all reinforcing materials, and it has corrosion resistance, can fully meet the salted soil, expanding soil construction of highway requirements. It has a unique application prospect.

-

Message Feedback

中文简体

中文简体 русский

русский عربى

عربى