1. Characteristics of high-strength polyamide industrial yarn

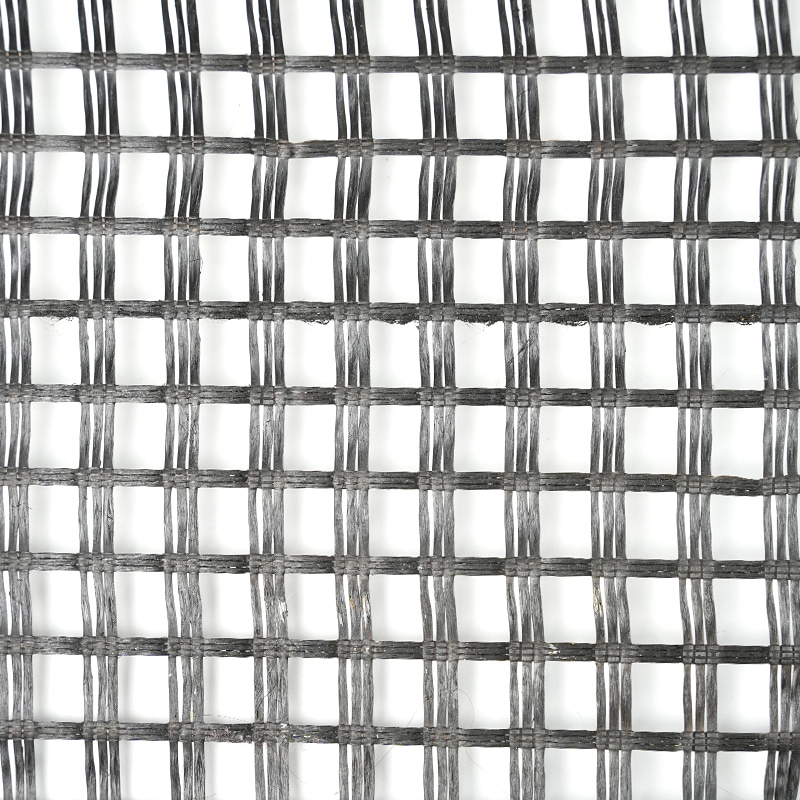

Polyamide industrial yarn, also commonly known as nylon yarn, is a synthetic fiber with mechanical properties such as high tensile strength and abrasion resistance. The polyamide yarn used in Warp knitted polyester geogrid not only provides strength, but also has the following characteristics:

High tensile strength: The tensile strength of polyamide fiber is much higher than that of traditional materials, which enables warp knitted polyester geogrid to maintain stability under heavy loads and is suitable for high-stress and high-load geotechnical applications such as roadbed reinforcement and embankment engineering for roads and railways.

Excellent wear resistance and durability: Polyamide fiber has extremely high wear resistance, which enables Warp knitted polyester geogrid to be used for a long time in complex environments, has an extremely long service life, and can resist friction damage from soil and stones.

Chemical corrosion resistance: Polyamide materials show good corrosion resistance in common acid and alkali environments, which enables the geogrid to maintain its structural strength in various complex soil and water environments, especially suitable for water conservancy projects and construction conditions with harsh environments.

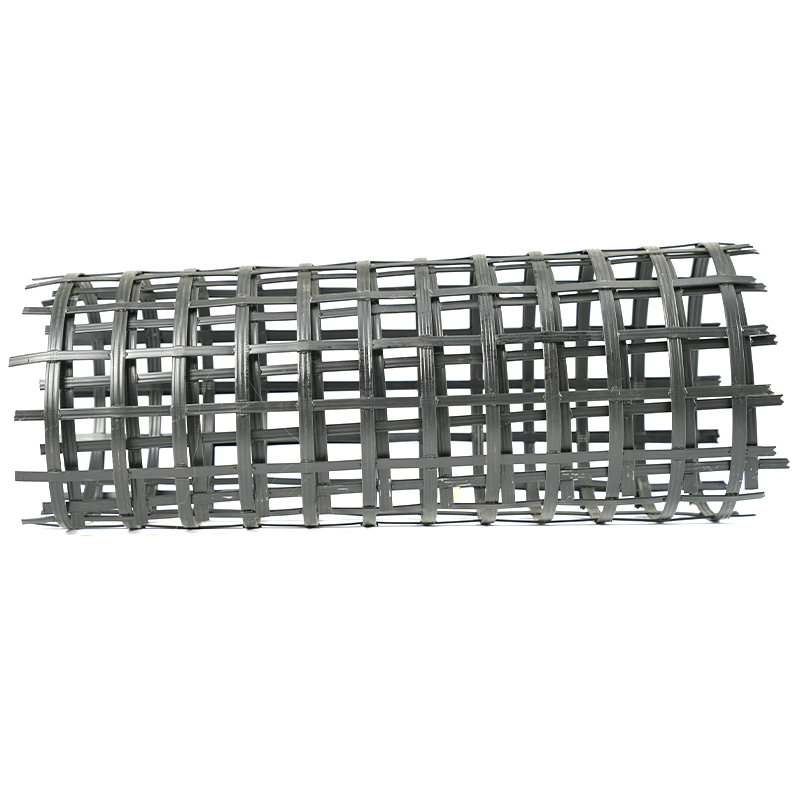

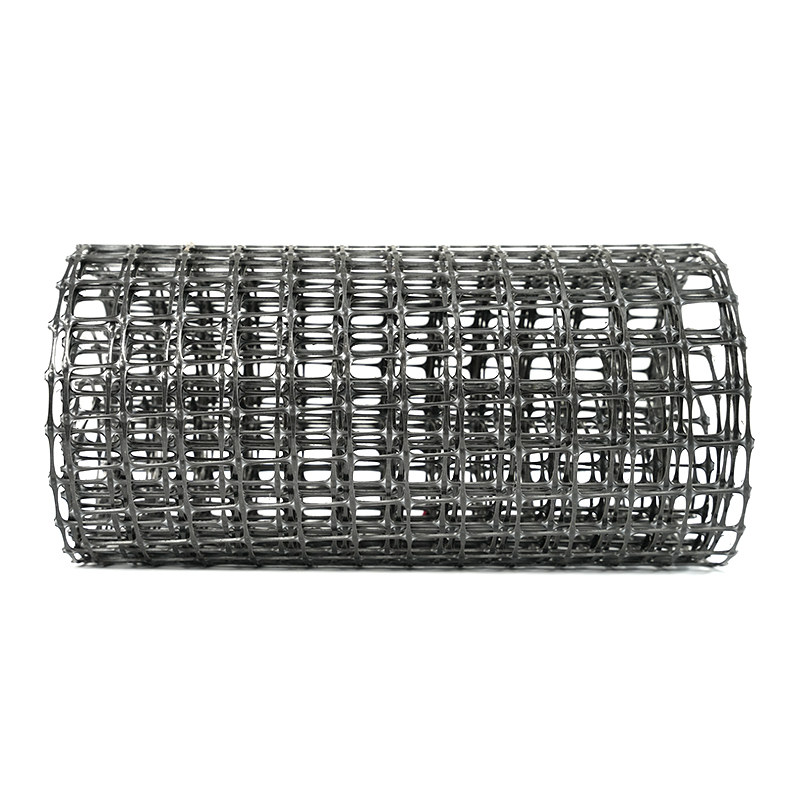

2. Unique weaving process of Warp knitted polyester geogrid

The warp knitting process gives Warp knitted polyester geogrid significant structural advantages. Unlike traditional weaving methods, the Warp knitted process forms a highly regular grid structure through directional weaving.

High tensile capacity of directional woven structure: Warp knitted polyester geogrid uses its unique warp knitting process to evenly distribute stress on each polyamide fiber when subjected to force, reducing local stress concentration and enhancing the overall tensile strength and toughness of the geogrid.

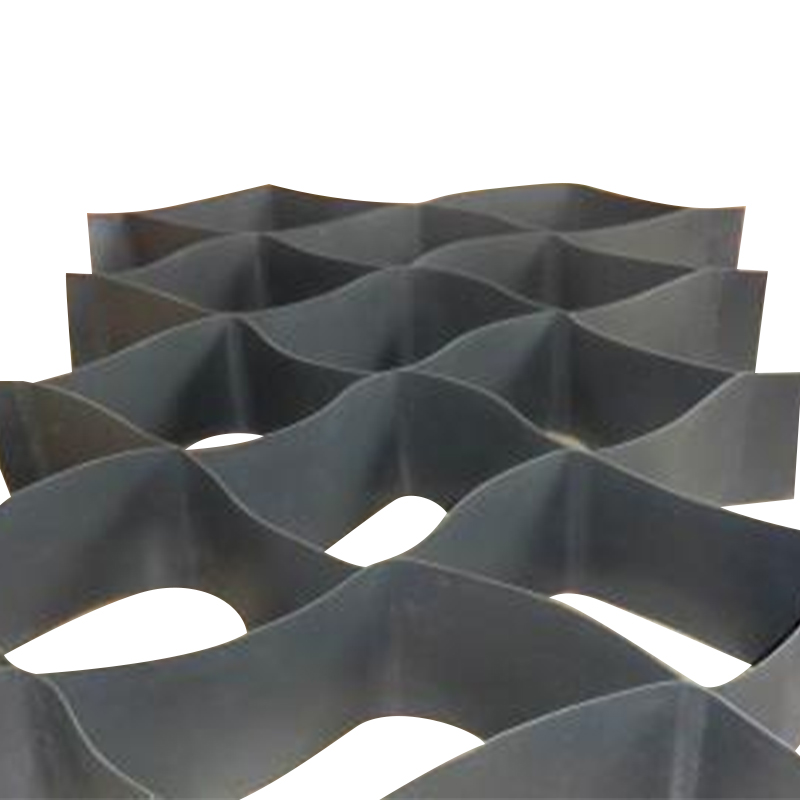

Strong bonding with soil: After coating, the Warp knitted polyester geogrid can form a strong bond with soil and gravel, further improving the overall stability of the foundation. The warp knitting process enables the pore structure of the geogrid to better fit with the filler, improves the friction between the soil and the grid, and effectively prevents sliding instability.

3. Application advantages of high-strength polyamide industrial yarn Warp knitted polyester geogrid

The application of Warp knitted polyester geogrid in soft foundation treatment and soil reinforcement projects is inseparable from the mutual cooperation of its material properties and weaving technology. The following are its unique advantages in engineering applications:

Enhance the bearing capacity of the foundation: Since the high-strength polyamide industrial yarn gives the geogrid grid a high tensile strength, Warp knitted polyester geogrid can effectively enhance the bearing capacity of the soft foundation and avoid excessive settlement or instability of the foundation. In high-load projects such as highways, railways and airport runways, geogrids can significantly improve the stability of the foundation and extend the service life of the road.

Reduce construction costs: The combination of high-strength polyamide industrial yarn materials and warp knitting technology makes Warp knitted polyester geogrid not only have performance, but also reduce the demand for other traditional reinforcement materials during use, thereby reducing the overall project cost.

Improve engineering safety and durability: Due to the corrosion resistance and wear resistance of polyamide fibers, Warp knitted polyester geogrid can still maintain its strength and integrity in soil, groundwater and climate conditions, ensuring the stability and safety of the project during long-term use.

4. Environmental protection and sustainable development advantages

In addition to the advantages in structural performance, Warp knitted polyester geogrid made of high-strength polyamide industrial yarn also shows its advantages in environmental protection. Compared with traditional materials such as steel bars and concrete, geogrid materials are light and energy-saving, and reduce damage to the natural environment during construction.

中文简体

中文简体 русский

русский عربى

عربى