1. Basic principles of hot-rolled spunbond process

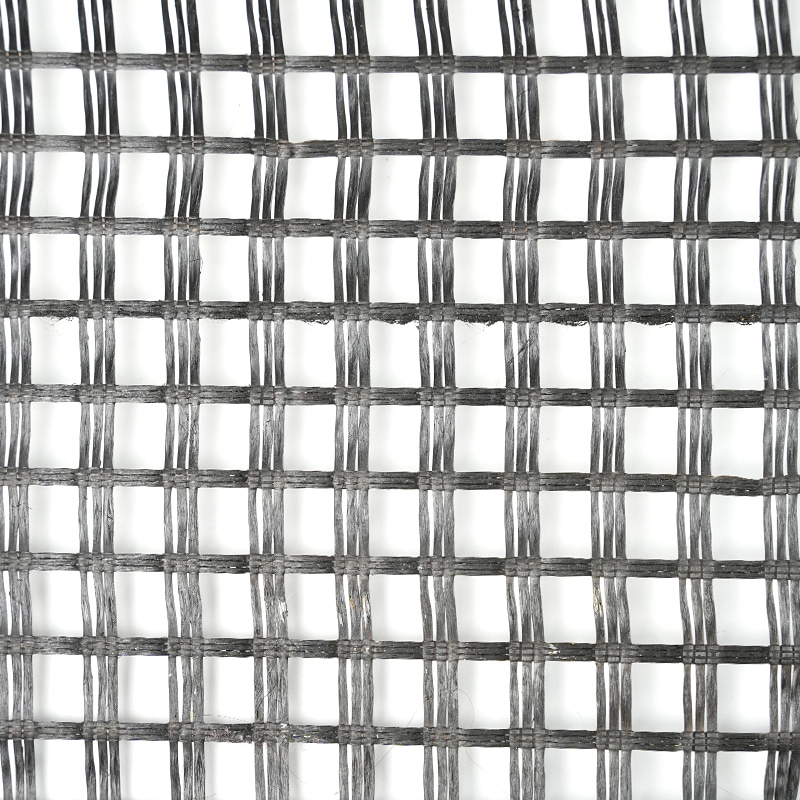

Hot-rolled spunbond process is a process in which polymer materials are formed into a fiber web through spinning technology, and then hot-rolled equipment is used to press and bond the fibers under high temperature conditions. Specifically, polyester particles melt at high temperature and form fine fibers through spinnerets. The fibers are evenly distributed into a web, and then heat and pressure are applied by a hot rolling machine to cause hot melt bonding between the fibers to form a tightly structured non-woven fabric.

The biggest feature of this process is that the fibers are fused by heat energy, avoiding the use of adhesives, thereby improving the purity and environmental performance of the material. At the same time, the uniform distribution of the fiber web and the precise control of the hot rolling process make the non-woven fabric in strength, air permeability, thickness uniformity, etc.

2. Effect of hot-rolled spunbond process on polyester hot rolled non-woven fabric

1. Improve material strength and durability

Polyester fiber itself has high tensile strength and toughness, and the hot-rolled spunbond process makes the fibers in the fiber web more tightly combined by hot pressing, further enhancing the overall strength and durability of the material. This makes the polyester hot rolled non-woven fabric show better tear and tensile resistance during use, and can adapt to more stringent use environments.

2. Provide better thickness uniformity and stability

Another significant advantage of the hot-rolled spunbond process is that it can produce non-woven materials with extremely high thickness uniformity. During the production process, polyester fibers are evenly distributed through spinning and then pressed through a precise hot-rolled control system. Through this process, the polyester hot rolled non-woven fabric can maintain a highly consistent thickness, which is very important for many high-demand application scenarios, such as medical, packaging materials and other fields that require precise thickness control.

3. Improve the breathability and feel of the material

The hot-rolled spunbond process not only improves the physical strength of the non-woven fabric, but also retains good breathability and soft feel. Polyester fibers are spunbonded to form a fiber web, and the gaps between the fibers are not completely destroyed during the hot rolling process, so the material still has a certain degree of air permeability.

4. Improve production efficiency and environmental protection

Compared with the traditional bonding process, the hot rolling spunbond process has higher production efficiency. During the entire production process, by precisely controlling the temperature and pressure of the hot rolling equipment, efficient fiber bonding and shaping can be achieved, greatly shortening the production cycle. The use of internationally advanced production and processing technologies ensures that Polyester hot rolled non-woven fabric can meet the market's requirements for environmental protection and sustainable development while being efficiently produced.

中文简体

中文简体 русский

русский عربى

عربى